Tools for Tomorrow

Innovative tools to help you fully exploit the benefits and freedom of additive manufacturing.

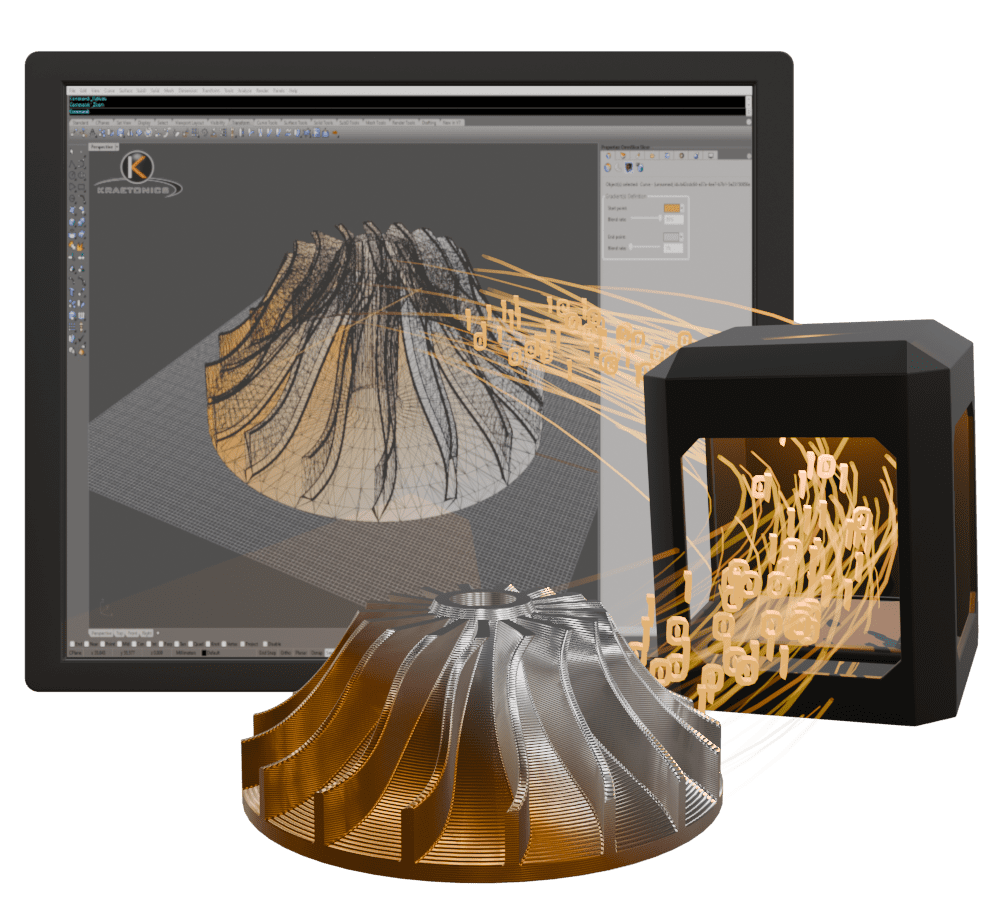

A modern slicer for advanced 3D printing

Do more with your 3D printer

OmniSlice® automates hybrid additive manufacturing, can build parts made of functionally-graded materials, and gives ordinary three-axis printers the ability to print off-axis and conformally, even on near vertical sidewalls.

take full advantage of the 3rd dimension

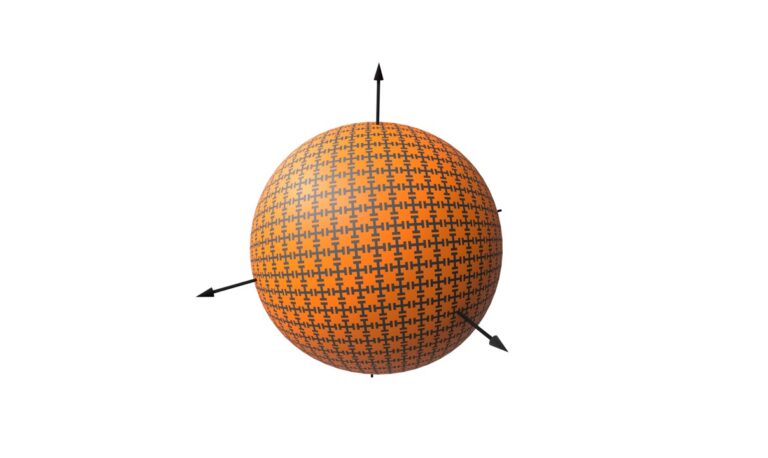

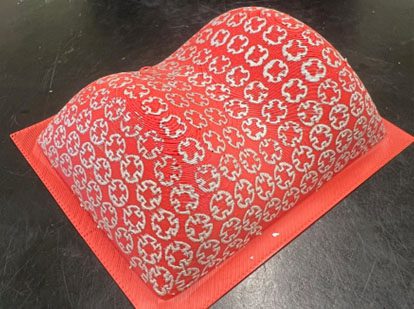

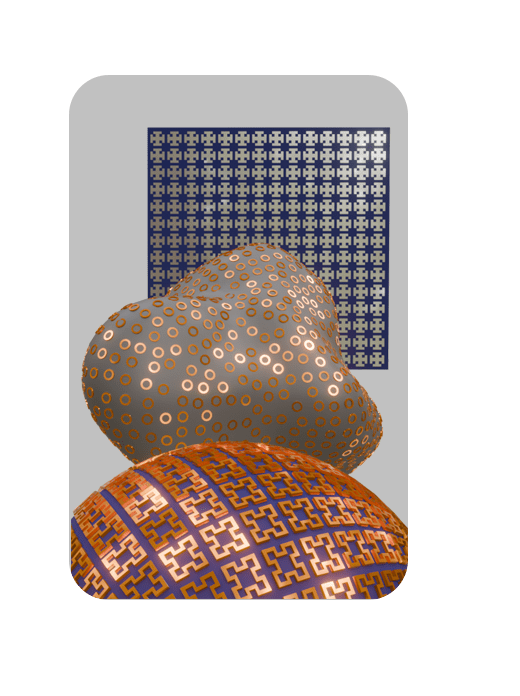

Wrap periodic structures over any surface

Kraetonics software gives you the ability to wrap virtually any periodic structure over irregular and double-curved surfaces with minimal deformations to the elements. This capability preserves the electromagnetic properties.

Who Are we?

We are an ambitious team of disruptive thinkers who develop ideas and tools that let our customers take full advantage of additive manufacturing.

Who partners with kraetonics?

Research and industry innovators looking to take full advantage of the new degrees of freedom additive manufacturing offers.

Learn what Kraetonics can do for you...

Your needs

- Contract R&D specialists in additive manufacturing, electromagnetics, software development and cyber security

- Resources to unlock capabilities hidden in your current printing platform

- New tools and ideas to better utilize the new degrees of freedom offered by 3D printing

- An adaptable ecosystem to meet your design and 3D printing needs

You need

- A slicer that is easily adapted to drive custom hardware and processes

- Installs as a CAD plug-in for an easy and intuitive interface that you are already familiar with

- Let our software drive your machine so you can focus on hardware development

- A resource to tap into an ecosystem bigger than just slicing software (cloud, design, slicing, etc.)

Your need

- Utilize our binary diversity technology to secure your clusters, embedded systems, and mass software installations

- Integrates seamlessly with your CI/CD workflow

- Use our procedures and metrics for quantifying the effectiveness of your security measures

Do you want to be an Innovator in Additive Manufacturing?

Kraetonics can help make it happen.

News from Kraetonics

Dr. Raymond Rumpf Motivates AMTA 2025 Audience with Keynote...

Kraetonics is proud to announce that CTO Dr. Raymond C Rumpf...

Kraetonics LLC has been awarded a two-year, $2 million contract...

How do you take a flat pattern or array and conform it to...

Kraetonics, LLC will be present at the 8th annual Military...