Kraetonics Awarded $2 Million Air Force Contract to Advance Design and Additive Manufacturing Tool for Next-Generation Electromagnetic Surfaces

WEST MELBOURNE, Fla, August 15, 2025 – Kraetonics LLC has been awarded a two-year, $2 million contract from the Air Force Research Laboratory to develop software tools and manufacturing technologies for next-generation frequency selective surfaces (FSSs). The project, beginning Aug. 8, 2025, and concluding Sept. 10, 2027, will be led by Dr. Raymond C. Rumpf, the company’s chief technology officer. The technology aims to enhance the Air Force’s capabilities in controlling and manipulating radio waves, providing a strategic advantage in modern battle environments.

WEST MELBOURNE, Fla, August 15, 2025 – Kraetonics LLC has been awarded a two-year, $2 million contract from the Air Force Research Laboratory to develop software tools and manufacturing technologies for next-generation frequency selective surfaces (FSSs). The project, beginning Aug. 8, 2025, and concluding Sept. 10, 2027, will be led by Dr. Raymond C. Rumpf, the company’s chief technology officer. The technology aims to enhance the Air Force’s capabilities in controlling and manipulating radio waves, providing a strategic advantage in modern battle environments.

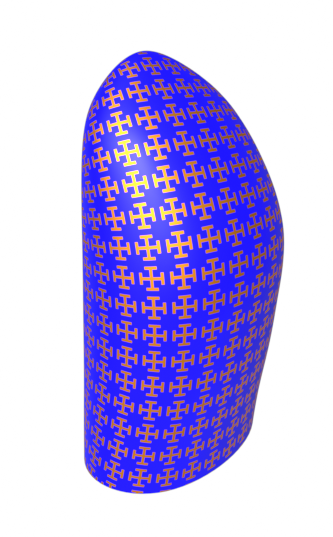

Frequency selective surfaces are patterned metallic surfaces used on aircraft, ships, autonomous vehicles, munitions, radomes and other platforms to block, redirect, absorb or otherwise control electromagnetic signals. Kraetonics has secured an exclusive license from the University of Texas at El Paso for advanced algorithms capable of wrapping these patterns across irregular and doubly curved surfaces without distorting the metal elements, preserving their electromagnetic performance.

By integrating this technology with Kraetonics’ flagship additive manufacturing software, OmniSlice®, Kraetonics will enable rapid design and 3D printing of structures containing the advanced FSS technology. This approach will significantly reduce the time from concept to manufactured device, allowing delivery in a matter of hours.

“This is an extraordinary capability we are developing for the Air Force,” said Rumpf. “It should be impossible to perfectly wrap repeated patterns over curved surfaces, but the algorithms we are using can do it. Combined with OmniSlice®, products can be moved from idea to finished hardware in mere hours.”

This animation demonstrates the challenges in wrapping a repeated pattern, like a Frequency Selective Surface (FSS), over an irregular or doubly-curved surface. This almost always distorts the size, shape, and spacing of the metal elements, which alters or erases the electromagnetic properties and capabilities.

Kraetonics is incorporating this extraordinary design capability into its software for additive manufacturing, OmniSlice®. The capability will allow users to easily and intuitively wrap patterns, like FSSs, over surfaces and to rapidly manufacture the devices.

The initiative aligns with Kraetonics’ mission to create tools and methods that maximize the potential of additive manufacturing in defense platforms. Kraetonics is an ambitious team of disruptive thinkers who develop ideas and tools that help its customers take full advantage of additive manufacturing through innovation, software, and advanced manufacturing techniques.